Polar Power, Inc. first tested its DC generator using its PMHH Alternator technology in 1992. Since then numerous organizations have performed extensive testing on our generators, including the US Army. Polar’s DC generator sets (gensets) meets both Military and Bellcore power applications.

The Polar DC Generators are designed and optimized to deliver high currents at low voltages which is required for battery charging and operating DC loads. No battery chargers or power supplies are required.

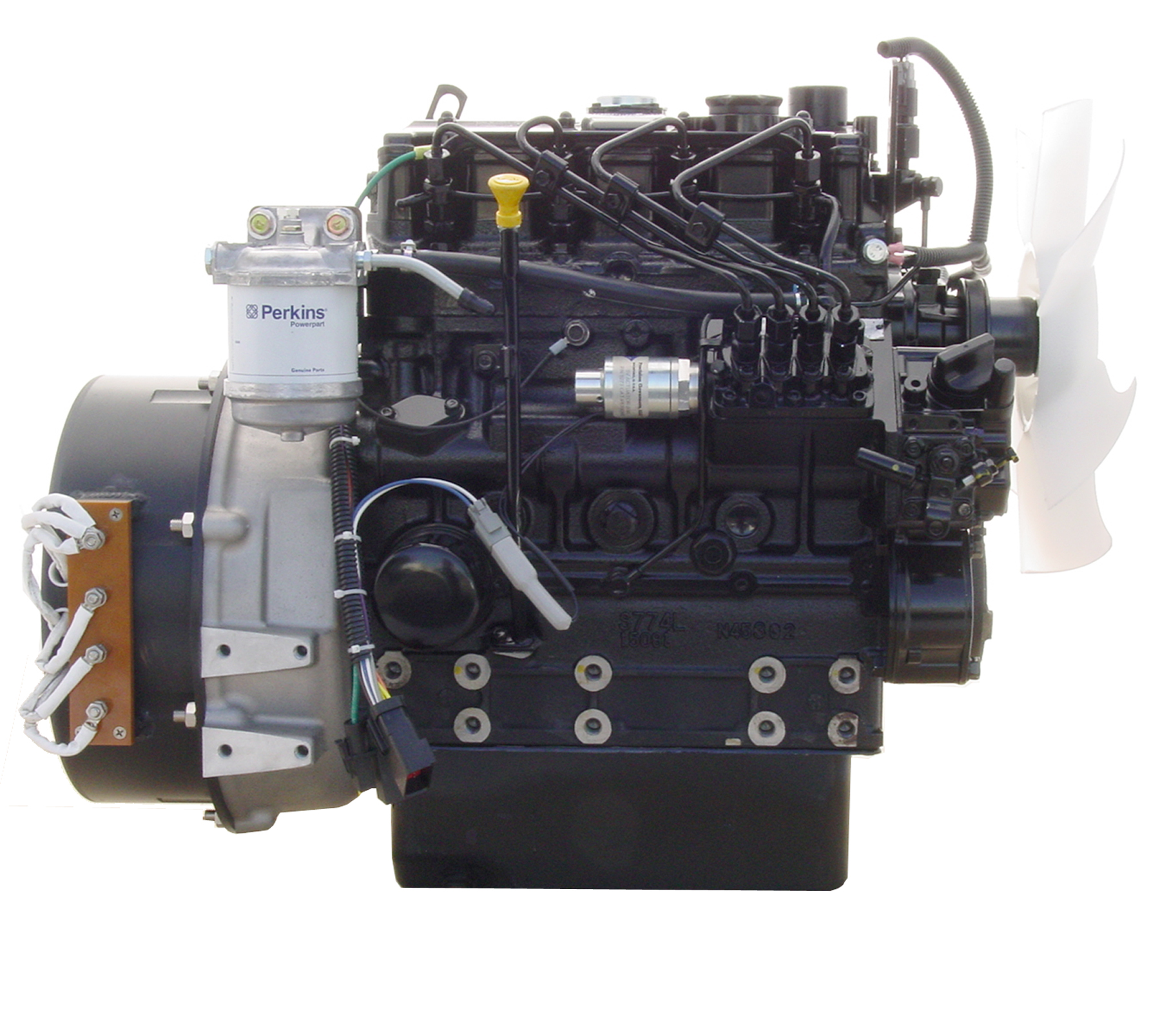

Polar assembles their generators to meet the clients requirements by adding the appropriate diesel, gasoline, or gas (propane, butane, natural gas) engine to their proprietary DC alternators. All engines are liquid cooled.

Polar has designed this DC alternator incorporating state-of-the-art technologies and all new tooling to meet the increased performance demand.

- Low Maintenance and High Reliability

- Low EMI Emissions

- Very High Quality Electrical Output

- Light Weight

- Low Fuel Consumption

- Low Acoustic Noise

- High and Low Ambient Operation

(-40° to 125° F)

Low Maintenance and High Reliability

- The unique alternator design allows us to turn the engine at low speeds, thereby extending engine life.

- The voltage regulator has automatic two step engine speed control. At high electrical load demands the regulator, through an external solenoid, automatically increases engine RPM; at low loads the engine speed is automatically decreased.

- Polar Power’s PMHH alternator has no: bearings, couplings, brushes, slip rings, nor rotating fields. There are no alternator parts to wear.

- The entire alternator assembly is vacuum dipped and baked with a polyester coating. This seals off all metal surfaces from corrosion. Resistance to salt fog is extremely high.

- There are no electronic parts (diodes, etc.) nor electrical connections inside the alternator. There is nothing to short or vibrate loose inside the alternator.

- The alternator is almost impossible to damage electrically. The outputs can be shorted for minutes without damage.

- The alternator is thermally protected; a sensor on the yoke can warn the operator of a high temperature condition. If no action is taken the regulator automatically reduces the output current so the alternator can run cooler.

- The output current is monitored by the voltage regulator through a current transducer. The voltage regulator has an adjustable current limit on the output. It is virtually impossible to overload the alternator.

- Polar Power’s PMHH alternator should have an MTBF exceeding 100,000 hours. The diode bridge set is remote from the alternator and mounted on a large heat sink to keep cool. The voltage regulator has lightning and surge protection on both the input and output. All the electronic components within the voltage regulator are operated at less than 50% of their rated values.

- The only normal wear the alternator experiences is the abrasion caused by the air being circulated around the stator coil and this effect is limited. Polar Power’s PMHH alternator, because of its high efficiency, does not require a cooling fan. Air moved over the stator due to rotor effect is of low velocity. This is advantageous in sandy and dusty environments.

- The engine is protected against: over-temperature, low oil pressure, over-speed, and over-cranking (during starting). There is a lockout protecting the engine against starter motor actuation while the engine is running.

- Two stage cyclone air filters are used on the engines air intake in order to minimize the air media cartridge replacement.

- The alternator’s rotor is dynamically balanced to improve the engine’s bearing life.

- Fuel is filtered to stringent standards for water and particle separation before entering the engine.

- Low EMI emissions are designed into the system. There are no brushes or slip rings. Field coil is isolated from the buss through fast diodes and capacitance. The voltage regulator does not strobe the field coil on and off. Proportional control reduces the back EMF produced by the field coil. The fuel stop and two speed solenoids are attenuated for voltage spikes as a result of turning on and off the solenoids field coil.

Diesel

- · Max Continuous Output: 5.5 kW at 2900 RPM

- · 100 amps at 54 VDC (200 amps at 28 VDC)

- · 2 cylinder diesel, water cooled

- · Engine Operational Life: 8,000 to 12,000 hr.

- · Very light weight

LPG and NG

- · Max Continuous Output: 15 kW at 3200 RPM

- · Available in all voltages from 24 to 500 Vdc

- · 3 cylinder water cooled engine

- · Engine Operational Life: 30,000 to 40,000 hr.

- · Very light weight